039 Defence force and aviation applications for wetblasting

Dana-Ridge wetblast units are in use in a great many of the defence force and aviation industries. The unique process...

Our

Customers

Defence Force Customers

Raytheon

Australian Submarine Corp.

Australian Army

Australian Navy

RAAF

Boeing

Aviation Customers

Standard Aero (previously Pratt & Whitney)

GE Aviation

Pacific Turbine

Alliance Airlines

Hawker Pacific

Safran Helicopter Engines

Leonardo Helicopters

Asia Pacific Aerospace

And more

Why are they so popular with defence and aviation?

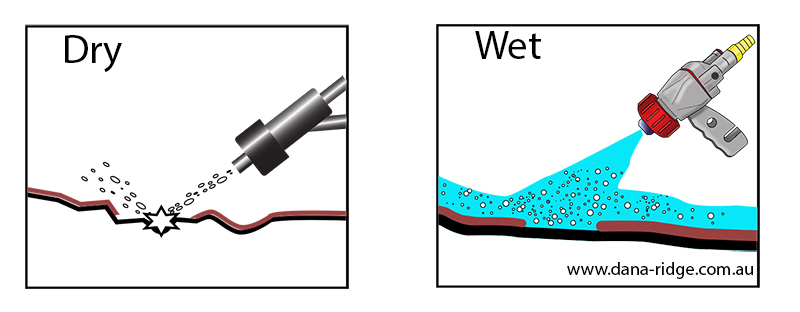

Dry Vs Wet Blasting

Dry blasting

Wet blasting

- Heat distortion

- Destruction of tolerances

- Poor finish that fingerprints easily

- Media impregnation into the part (a BIG negative when considering aircraft components)

- need to degrease/preclean before blasting

- DUST

- Simultaneous degreasing and rust inhibition

- Removes surface deposits , scale and light burrs

- Cleans plastic and rubber

- Gentle on mating surfaces and soft metals but powerful enough to remove paint and powder coating

- Water supression means no dust issues = safer

- Wider ranges of finishes available

As you can see above, wet blasting is far superior when it comes to blasting important components used in the areas of aviation and defence.

When it comes to bringing parts back to life without destroying them in the process, wetblasting is the way to go.

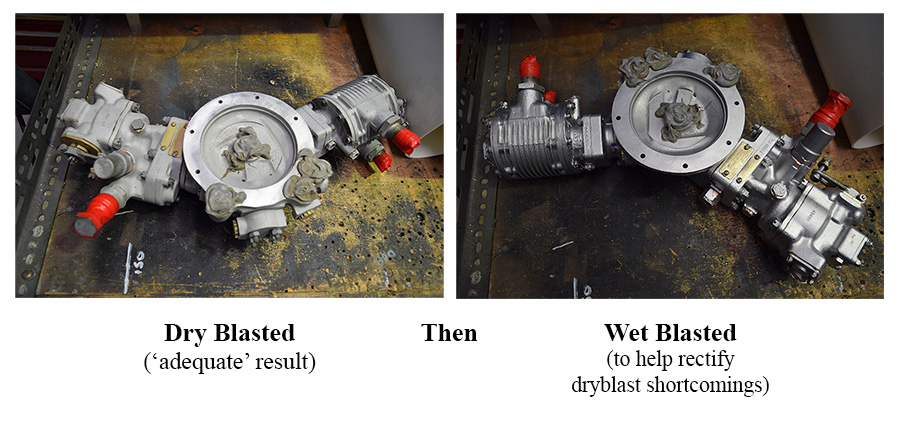

Nearly ruined with dry blasting this part from a vintage war plane was brought to us to see if we could improve the finish further. Although impossible to undo the damage caused by the dry process, we were able to improve it without doing further damage. You can see more about that by clicking the button below

Vintage Rolls Royce Merlin engine

Learn more about dry vs wet blasting here

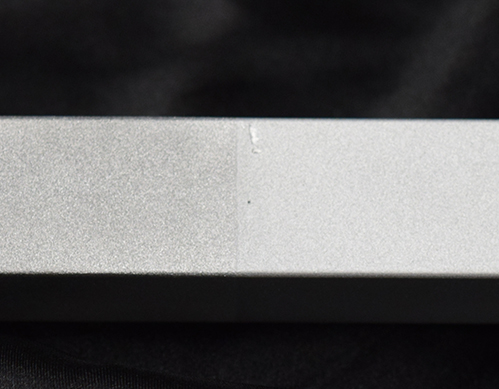

Right = wet blasted

Aluminium square bar blasted with the same glass bead at the same pressure. Even using such a large bead the wet process leaves it for dead.

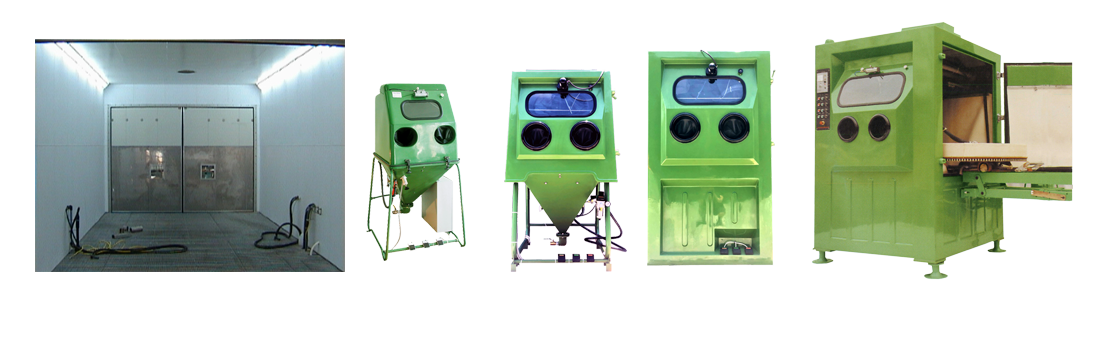

There’s a machine to suit

Mercury

Small footprint for when space is tight

Comet

Second most popular unit. Generous cabinet

Mars

Most popular unit. A powerful workhorse

Titan

A monster unit. Manual or semi-automated versions available

Other

Modified, custom or walk-in options available.

All options

Industry Applications

Gallery

Videos

Wet vs Dry

Tips and Tricks

Blast Abrasives

Environmental benefits

Blog updates

The Process

Learn more about the Dana-Ridge Process

Learn More

“I bought a Wet-blasting machine from these guys 10 years ago, and we have used it in a commercial capacity. It gets used most days and some times for 3-4hrs a day.

It has been great, super reliable, no major problems or failures, we do maintain it on a regular basis but probably less than is recommended (Sorry).

I can’t thank the Guys at Dana Ridge enough for all their help and advice and superb service over the years, they have always been there if we have needed them.

If you’re looking for a Wet-blasting machine I highly recommend them.”

Martin NormanHysideTrading – Mercury model

“After using these machines in my business for over ten years now, I would highly recommend Dana Ridge for their prompt service and ease of dealings. I have two of their machines and having dealt with other machines available on the market I would not go past these.”

John Ferntree Gully Hydroblasting – Comet and Mars models

“Here at Sheppards Diesel Service we have being using the Wet Beadblaster for over 15 years and it is still going strong. Dana-Ridge are only a phone call away for any assistance and spare parts. This machine makes life a bit easier and the end presentation back to the customer of their item in for repair makes it look like new.”

Neil QuickSheppard’s Diesel Service – Mars model

“Dana Ridge wet blast machines are by far the best way to clean or finish a component. They leave dry blast machines for dead. Little maintenance is needed and when it is parts are always in stock, even for very old machines.”

Les JonesDavid Jones Autos – Mercury model

“Have purchased two wet blaster units over many years and have always found the staff and management very helpful with any parts, help or service required. Can highly Recommend Dana Ridge for peace of mind service.”

Ian CulshawDirector – Alltorque Engineering – Comet model

“Very well recommend using this company, great customer service and knowledge of the product they are selling”

Robert McKenzieRGM Painting – Comet model

“Fantastic to deal with very quick at getting orders out highly recommend these guys”

SarahDiesel Pump Caboolture

“Great service and fast shipping from Allan”

Niazi HelouAll Drive Subaroo – Jupiter model (1989)

We couldn’t be happier with our Mars Wet Blaster. The machine is reliable, simple to use, and easy to maintain. It can be long periods between uses, then intense use for entire days, and the machine functions wonderfully. We thoroughly recommend Dana-Ridge for service, advice, and rapid response.

John

Great service from a staff who show a vast knowledge of, and great enthusiasm for, the equipment they sell and service. Top quality gear, and top quality back-up service from these guys. Seriously, I can’t recommend them highly enough.

Stephen ProsserComet Machine

Dana-Ridge equipment and after sales service is second to none, always willing to help and a wealth of knowledge you can’t put a price on. Best in the business.

Mark ElliottOwner – Pioneer Finishes

I purchased a Vapour blasting cabinet from Allan at Dana Ridge 3 years ago. Allan and his team have been fantastic in providing after sales support and supplies to keep my machine running at its best. I highly recommend Dana Ridge machine as well as Allan and the greater Dana Ridge team

Chris MauerhanMotoREcycle

Great Service Great PEOPLE

Robert OehlertB&W MOTORCYCLES

Previous

Next

Get in touch with us today

Once you have one of these machines, you’ll wonder how you ever got along without it!

Contact Us