026 How to maximise the media life in a Dana-Ridge wet blast unit

How to ensure you don't use excessive water or media

Wetblasting gives much longer media life, saving you money. Learn how to maximise this advantage…

A great feature of the Dana-Ridge wetblast process is the longer media life that is achieved compared to the dry blast process. It allows big cost savings while also achieving a far wider range of surface finishes.

What is media?…

When we talk about “media” we mean the type of abrasive that is being used in the machine. This can be anything from glass bead, to soda, to garnet and much more. You can learn more about the wide variety of available options by clicking below…

What causes excessive media consumption?

There can be several reasons for excessive consumption of media in your Dana-Ridge wet blast unit and are all easily solved as follows…

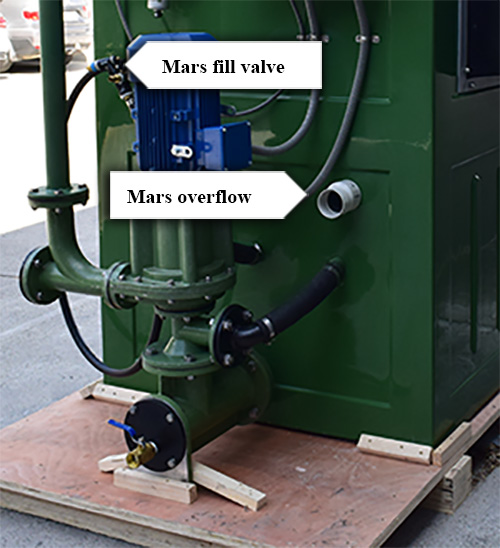

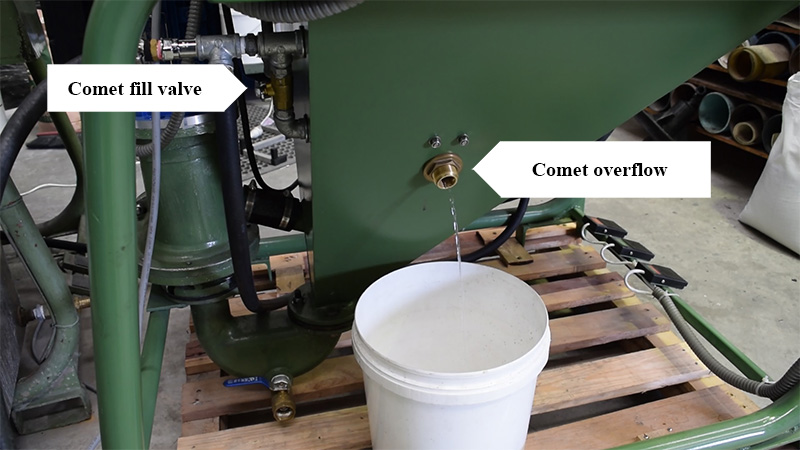

- Fill valve left open…

Each machine has a valve at the rear that is used for the initial fill of the machine. On the smaller machines it also doubles as an easy method for stirring up fine grade media after periods of inactivity.

During normal use this valve should remain closed. If not, then rather than just worn media going out the overflow, useful media will also be lost.

SOLUTION: Ensure the valve is kept closed during use

2. Excess water on the viewing window

- There is a valve on the front of the machine that controls the flow of water from the window spray. Similar to the problem above, too much can cause excess water to flow into the sump causing excessive media loss. Losing overly worn media from the overflow is a good thing, but losing useful media just adds unnecessarily to the cost of operation.

SOLUTION: keep the window wash as low as possible. Just enough to wet the wiper blade is enough.

3. Blasting at too high a pressure

- The highest pressure you will need to blast at is around 5.5-6.2 bar (80-90 psi)

Any higher and you start to remove the cushioning effect of the water and it acts more like a dry blaster thereby chewing through the media and losing the benefits of the wet process.

SOLUTION: Use the regulator on the machine to control the pressure level.

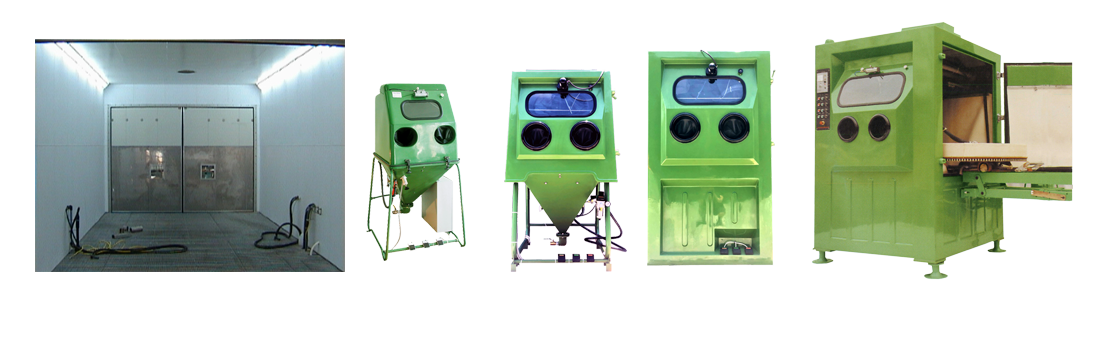

Machines available

tips and tricks

Worn Media

Get in touch with us today

Once you have one of these machines, you’ll wonder how you ever got along without it!

Contact Us