034 Choosing the right machine for you

How to choose the wetblast machine that is right for you.

Choosing the right machine

Finding a wetblast machine to suit your needs is not as difficult as you might think

Wet Abrasive Process

Our wetblast units operate using a similar principle. A thorough mix of water and blast media is recirculated through the process gun where it is atomised using compressed air. The result is a unique combination of properties that allow a wide variety of finishes on a wide variety of surfaces.

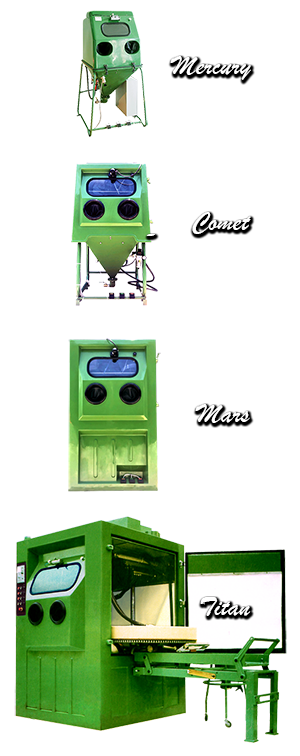

Internal cabinet size

Probably the first question is whether the parts you want to blast will actually fit in the cabinet including enough space to maneuver your process gun

Height above turntable 620mm

Depth (front to rear) 670mm

Width 680mm

Height above turntable 730mm

Depth (front to rear) 900mm

Width 890mm

Height above turntable 920mm

Depth (front to rear) 1030mm

Width 1050mm

Height above turntable 1080mm

Depth (front to rear) 1660mm

Width 1500mm

Saturn (Custom cabinets)

Neptune (walk-in blastroom)

Varies

For a size comparison, click on the link below

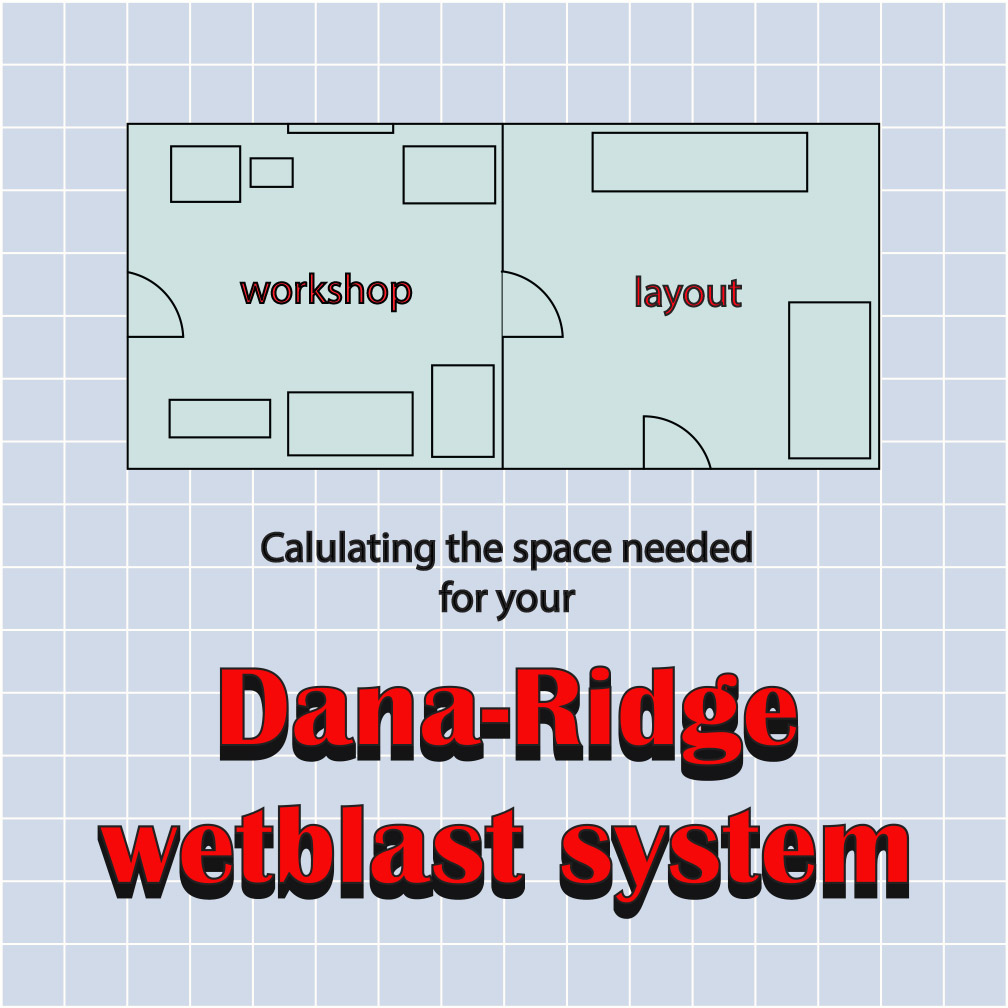

External cabinet size

Make sure you have enough space in your workshop for the machine itself

Height 1760mm

Depth (incl pump) 1020mm

Width 910mm

Working height at gloves 1270mm

Height 1970mm

Depth (incl pump) 1230mm

Width (door closed) 1000mm

Width (door open) 1770mm

Working height at gloves 1230mm

Height 2040mm

Depth (incl pump) 1680mm

Width (door closed) 1160mm

Width (door open) 2000mm

Working height at gloves 1180mm

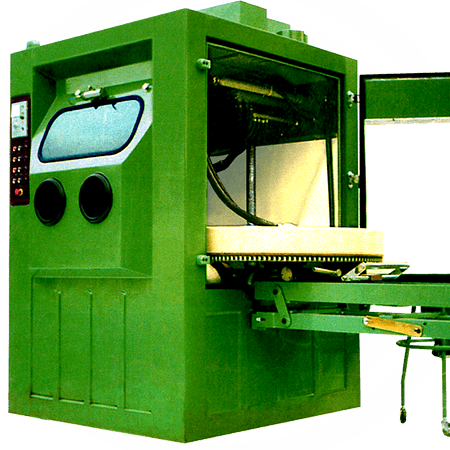

Height 2520mm

Depth (incl pump) 2120mm

Width (door closed) 1500mm

Width (door open) 2750mm

Loading height 960mm

Working height at gloves 1230mm

Varies

For more detail with diagrams please check out our blog post on the subject

Turntable capacity

Turntable diameter 500mm

Weight limit 50kg evenly distributed

Manual operation

Turntable diameter 500mm

Weight limit 50kg evenly distributed

Manual operation

Turntable diameter 700mm

Weight limit 200kg evenly distributed

Manual operation (in standard configuration)

Turntable diameter 1250mm

Weight limit 750kg evenly distributed

Manual operation in base model (electrically operated in semi-automated version)

Varies

Pump Power

1.5kW 2-pole motor

240V, single phase 50Hz

1.5kW 2-pole motor

240V, single phase 50Hz

Also available in 415V 3-phase upon request

4kW 2-pole motor

415V 3-phase 50Hz

7.5/11kW 2-pole 2 speed motor

415V 3-phase 50Hz

415V, 3-phase 50Hz

To learn more about the electrical requirements of each machine please click on the link

Air supply

15-26CFM (425-736 LPM) of free air

18-30CFM (510-849 LPM) of free air

18-34CFM (510-963 LPM) of free air

40-60CFM (1,132-1,699 LPM) of free air delivery per process gun

40-60CFM (1,132-1,699 LPM) of free air delivery per process gun

To learn more about the compressed air requirements of each machine please click on the link

Water supply

The Dana-Ridge wetblast units recirculate water and abrasive around and around. There is however, some water used to lubricate the wiper blade on the viewing window and also when using the rinse gun to rinse off any remaining media after blasting. The standard machines tend to use a similar amount of water of roughly 24L per hour. This can be taken to near zero consumption through the use of the optional closed-loop system.

Closed loop system

Water consumption

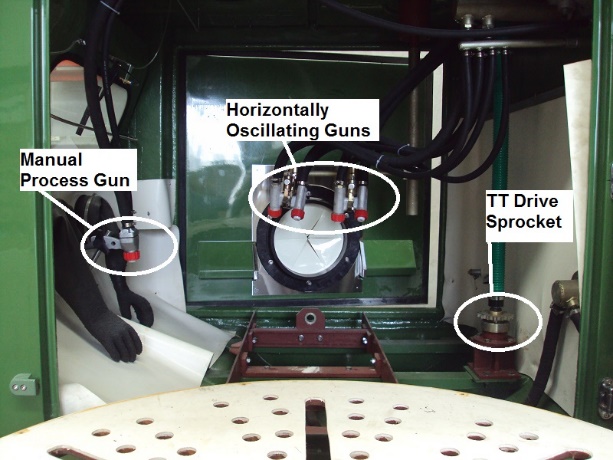

single or multi-gun

Single process gun only

Single process gun only

Single process gun as standard but pump is able to power more if desired

Single process gun as standard on the basic model. Semi-automated unit has 5 process guns

Varies

Anti cavitation feature

Mercury

Comet

Mars

Titan

Saturn (Custom cabinets)

Neptune (walk-in blastroom)

Larger machines have an anti-cavitation feature. It means that on initial start-up the pump will draw from the top of the sump before drawing from the bottom. This has several advantages. If the machine is overloaded by the operator with media, it will ensure the pump will not operate dry which could lead to pump failure. It also allows the pump to get the media flowing more efficiently on start-up. It is more forgiving in a workshop where the “attention to detail” is lacking or the new apprentice is let loose for the day.

Get in touch with us today

Once you have one of these machines, you’ll wonder how you ever got along without it!

Contact Us