032 Dosing Rates

Having put your machine (and closed loop tank if purchased) in the desired location and connected services such as compressed...

Having put your machine (and closed loop tank if purchased) in the desired location and connected services such as compressed air, water and electricity the next step is to fill your machine with water, media and any additives that you may require.

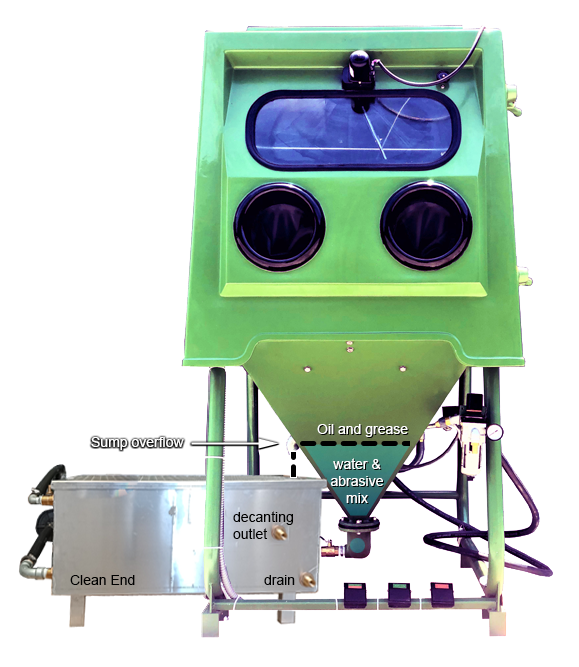

1. Fill the machine with water

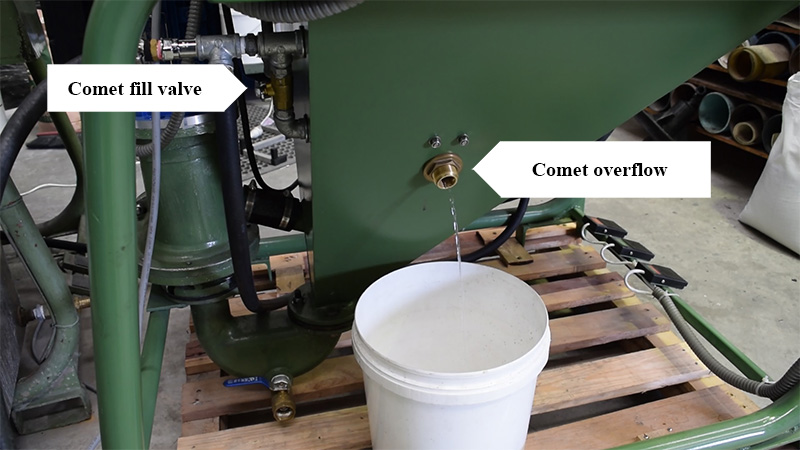

Use the water fill valve at the rear of the machine to fill the sump (or from a hose if you are independent from the water supply with the closed-loop system). Make sure the drain valve at the bottom of the machine is closed and continue filling until water starts to dribble from the overflow (as pictured) and then stop.

Sump water volumes

Mercury = 26L

Comet = 28L

Mars = 125L

Titan = 250L

2. Fill the closed loop tank with water

*Note* Closed loop tank may also be referred to as a settlement or recirculating tank.

For Mercury and Comet machines a 200L tank is supplied and for Mars and above, a 240L tank is utilised.

Fill it up on both sides 2-3 inches from the top of the tank.

Make sure that the gate valve on the recirculation tank pump is left slightly open to allow water to continuously flow through the pump to prevent ‘dead-heading’ leading to premature wear.

3. Add the VR20 ‘NO RUST’ (optional)

*Note* No rust is not necessary for the process itself and is not required for non-ferrous material such as aluminium, brass etc

VR20 is a temorary rust inhibitor that can be used within the machine or separately. It is usesful when blasting anything with a high iron content. Dosage in the machines is generally at 2%. If you go higher than this there may be some foaming through the agitating action of the process.

If you would like a higher dosage (if blasting cast iron for example that rusts more readily) then you can set up a ‘dunk tank with water that you can dose at 6-10% VR20. You would then rinse your blasted parts afterwards with the added advantage of being more effective than rinsing with the rinse gun alone.

VR20 NO RUST Dosing rates per machine

4. Add the media

Now that you have the machine filled you can add the blast media of choice.

Rather than putting the media directly into the sump, it is recommended to place it on the turntable and wash it down using the process gun.

Initial amounts:

Mercury or Comet we recommend starting with 1.5-4kg.

Mars we suggest a full 25kg bag

Titan, 2 x 25kg bags

How to add media

Choosing media

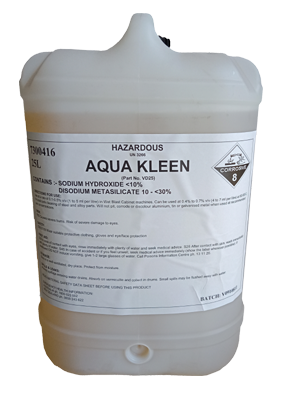

5. VD25 ‘Aqua Kleen’

*Note* Also optional

Available in a 25L drum, VD-25 is a specially formulated, high alkaline, low foaming, detergent additive. It is used to cut through and penetrate oil, grease and soil. It keeps these contaminants in suspension for removal through the Wet Blast machine overflow.

Using a measuring cup add product to achieve a 0.10% to 0.25% concentration in the machine sump. This concentration level will gradually dilute with machine operation, depending on the volume of window wash/rinse gun used.

To replenish concentration levels add the appropriate quantity of VD-25 every eight (8) operating hours (not necessary when using the closed loop system as there is no loss)

VD25 AQUA KLEEN Dosing rates per machine

Contact Us

We are here to help