Back to Blog

027 Workshop Space and Wetblasting

How to optimise your workshop space to include a Dana-Ridge wet blast unit.

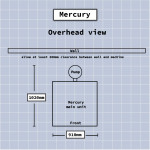

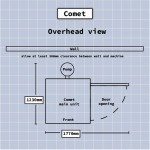

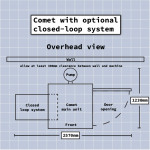

Workshops by defininition are are busy areas. Often customers are keen to find out how much of their floorspace needs to be dedicated to their cleaning/surface finishing equipment.

There are several factors to consider in locating your machine

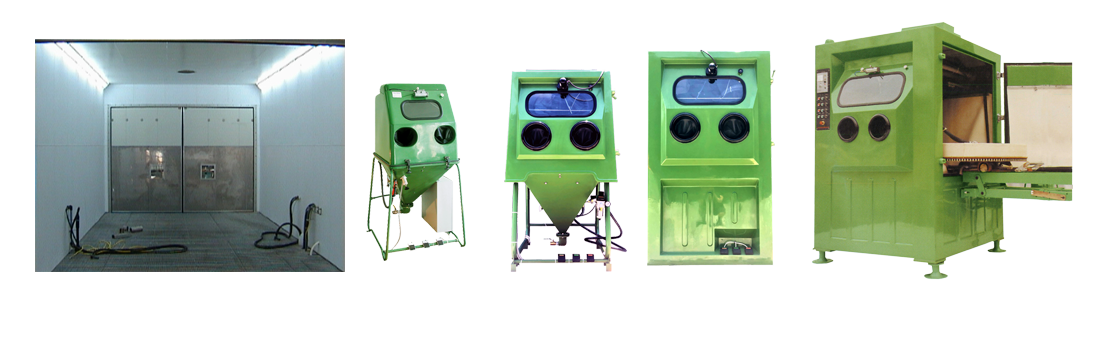

- Door access – Depending on the machine, there may be a flip top lid, a right hand door or both right and left hand door access.

- Compressed air – Depending on the output of your compressor you will typically want to keep the distance from the compressor to an air tool as short as possible to minimise pressure losses.

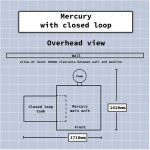

- Access to mains water (unless utilizing the optional closed-loop system)

- Location of electrical outlets

- Distance from the machine overflow to drain (unless utilising the optional closed-loop system). You will want to keep the distance as short as possible to prevent the build-up of fines.

water, drainage and compressed air considerations

Optional Closed-loop System

Machine installation

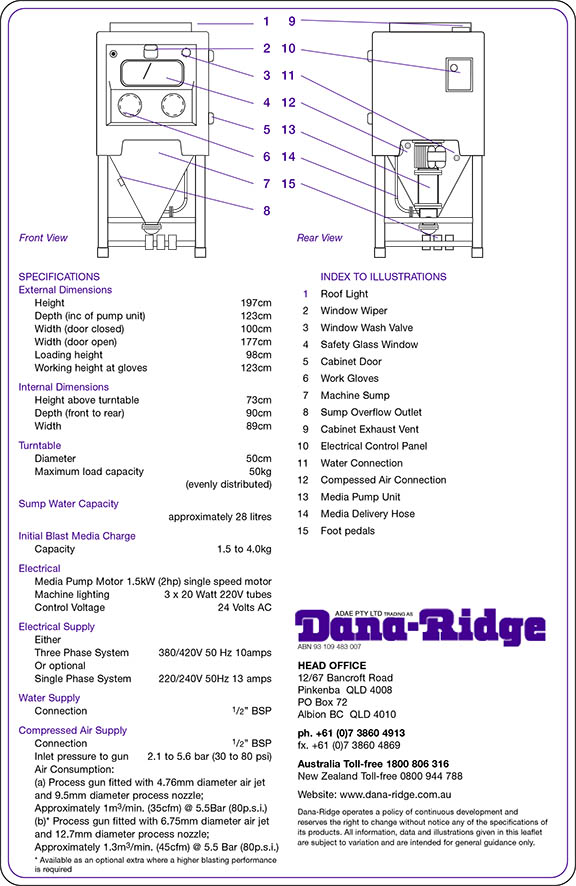

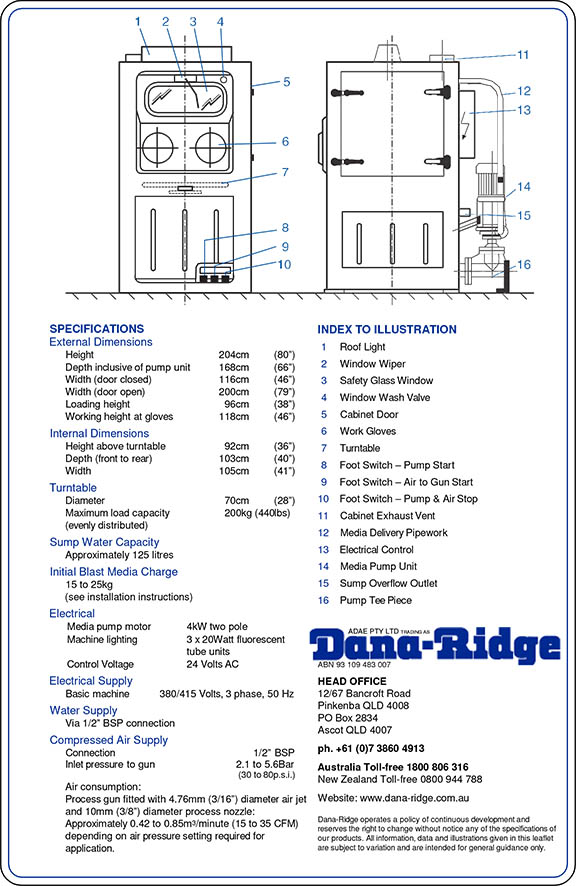

Machine Internal dimensions

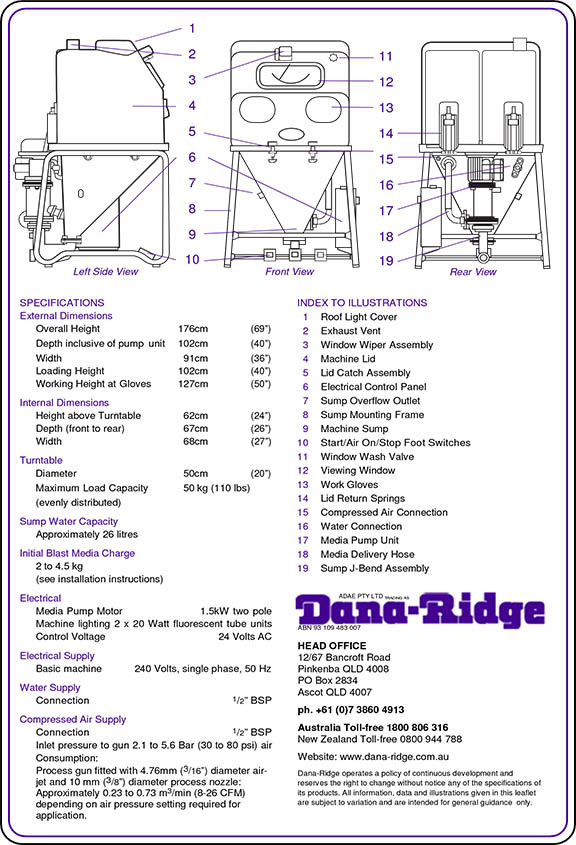

The Mercury

The Comet

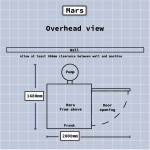

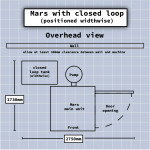

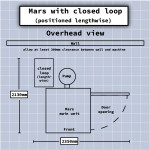

The Mars

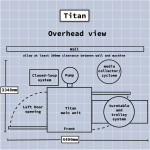

The Titan

Get in touch with us today

Once you have one of these machines, you’ll wonder how you ever got along without it!

Contact Us