024 water, drainage and compressed air considerations

Water, drainage and compressed air considerations when installing There are two ways to set up the wetblast machine in your...

Water, drainage and compressed air considerations when installing

There are two ways to set up the wetblast machine in your workshop

1. Open loop

Some water loss from the machine overflow due to the introduction of fresh water for the window spray and rinse gun.

(Approx. 24L/hr)

2. Optional closed loop system – where the water from the overflow is captured, filtered and then returned to the machine to complete a circuit.

(Reduces water consumption to almost zero)

Advantages of the closed-loop system

WITHOUT the closed loop system…

Direct the overflow into an appropriate drain, bearing in mind it will contain:

- Very worn abrasive that has become too small to do useful work

- Any optional additives such as ‘No Rust’ or ‘Aqua Kleen’

- Any blasted material such as paint flecks etc

- Any oils or chemical present on the parts you are blasting

Important

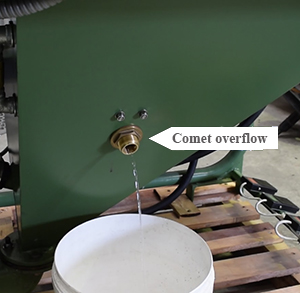

If attaching your own pipe work to the overflow make sure:

- It is relatively short

- Doesn’t have too many bends or kinks or restrictions

- Has a “fall’ to allow material to flow easily

- Pipework is easily removable for periodic clearing. This can be done using union connections and by not permanently fixing pvc pipe to the unit with pipe glue.

Otherwise, silts may build up over time and cause blockages.

When in operation, the amount coming out of the overflow should equal the amount of water being consumed by the window wash and the rise off gun (used to wash off remnant media after blasting).

If there is excessive water coming out the overflow, check that the fill valve is closed.

WITH the closed loop system…

Direct the overflow into the settlement tank:

• Position the tank either directly under the machine overflow or using pipework (observing the provisions above).

• Connect the hose provided from the tank pump to the machine water inlet.

Get the most out of your compressor

When connecting the air compressor, use a ½” diameter hose and avoid nitto style fittings that reduce flow.

Be aware that the longer the hose from your compressor to your wetblaster, the more air/pressure will be lost on route.

Air requirements

Machine Installlation

Get in touch with us today

Once you have one of these machines, you’ll wonder how you ever got along without it!

Contact Us