Our

Process

Learn more about the Dana-Ridge wet blasting process.

Partnering with industry to Finish Better

We aim for Dana-Ridge to be the name associated with Australian wet blast systems. We take pride in exceeding our customer’s expectations by providing leading systems, excellent service and friendly, helpful advice.

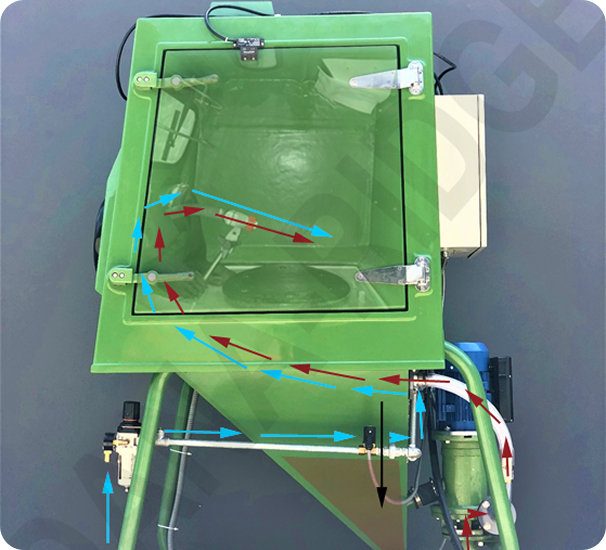

How does it work?

The cut-away picture shows how the Dana-Ridge wetblast process works. The machine thoroughly agitates the media and water and draws from a collection point at the bottom of the sump. It allows a highly efficient blast compared to other methods of wetblasting.

FAQs

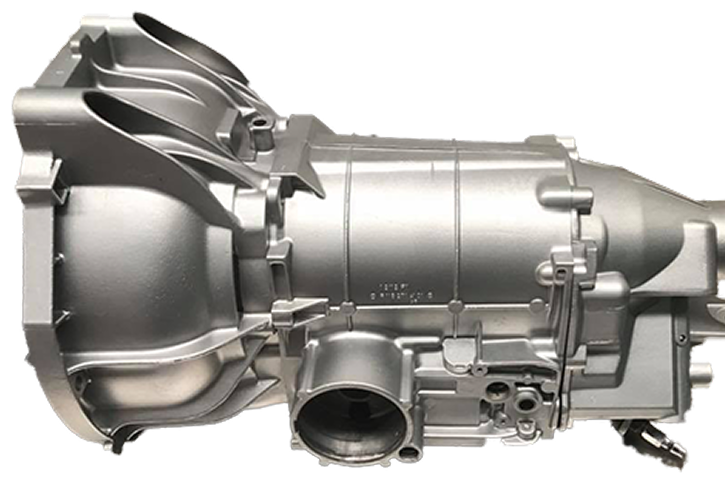

One-step surfaces

Its one-step cleaning and blasting process it eliminates the need for component pre-cleaning and degreasing and you don’t have to worry about leaving fingerprints behind when you touch the brilliantly finished part.

About Dana-Ridge machines

They’re environmentally friendly and less hazardous to user health with its dustless operation. Also, there’s no need for an expensive filtration system. You can blast with finer or coarser media than a dry blaster and blast items that would get destroyed in a regular sandblaster. Being heavy duty commercial grade machines means they can provide a greater volume of media to the gun at a greater flow-rate. These increase both the efficiency and the range that these machines are capable of. Very important considerations when time is money for your operation.

Why use Dana-Ridge?

Systems such as the venturi, pressure pot, vapour blaster, as well sandblasting and non-commercial units, are marketed as surface finishing machines, but are often geared towards home hobbyists and yield inferior results.

The Dana-Ridge wet blast system provides upgrades your commercial and industrial surfaces with unparalleled finishes.

Upgrade your surfaces and finishes

- Superior smooth or rough surfaces

- Multi-gun operation

- Rust Prevention

- Pump agitation

- Degreasing and rust inhibition

- Recirculation of media

- Reduced costs & prolonged life

- Maximised space & easy access

- Removal of contamination