Our

Industries

Our wet blast systems are used in a variety of applications and industries.

Blasting across industries

Following are just a few of the that industries that commonly use our equipment to improve quality, productivity and engineering standards.

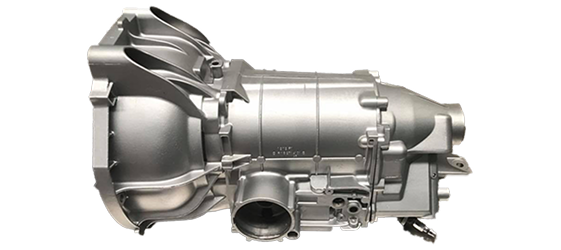

Automotive

A popular use for the wetblast process is the restoration/cleaning of components on cars, motorcycles and trucks, both vintage or modern. It is also used in the wheel repair business.

The wide spectrum of finishes available; from bright through to matte, combined with the ability to remove rust, paint and carbon deposits leaves customers in awe.

Aviation

Used by a number of aviation manufacturers, the Dana-Ridge wetblast process is safer than dry blasting for both the operator AND the components. The difference makes the Dana-Ridge wetblast unit the obvious choice.

Customers include:

Standard Aero | Pacific Turbine | GE Aviation | Hawker Pacific

Leonardo Helicopters | Asia Pacific Aerospace | Alliance Airlines

Defence Force

and more…

Contract Blasting

Set up a business for yourself doing contract blasting of customer components. You’ll be surprised with some of the things you will be asked to clean. Even more unusual requests such as etching stone, frosting glass or cleaning plastics and rubber can be accommodated. Not to mention the amazing job it does on a range of metals. With its huge versatility, you will have customers stunned at the results.

Defence Force

Our systems are used by a number of Defence force sectors and contractors:

- Raytheon

- Australian Submarine Corp.

- Australian Army

- Australian Navy

- RAAF

- Boeing

Electronics

What other process can be powerful enough to remove paint and powdercoat from steel but can also be set up to remove laquer from a circuit board while leaving the copper tracks intact?

Extrusion dies

Several customers use our machines to restore extrusion dies. The process cleans them up without destroying them like you would in a dry unit. Dies can be very expensive so keeping them in good working order for longer means huge savings. The wet blast process is the way to go.

Jewellery

Clean investment casting with no fuss. Customers include:

- Michael Hill Jeweller

- Palloys

- Sapphire export

- Wallace Bishop

- Morris & Watson

- Lenrose Creative…

Marine

Marine equipment is subject to a harsh environment and parts can get into quite a state. The great thing about the wetblast process is that you can make stainless steel, copper, brass and aluminium look like new without destroying the component. Perfect for marine applications.

And many more…

- Mining

- Energy sector (renewables and legacy)

- Scientific research

- Engineering and construction projects

- Wheel restoration

- Food equipment manufacturing…